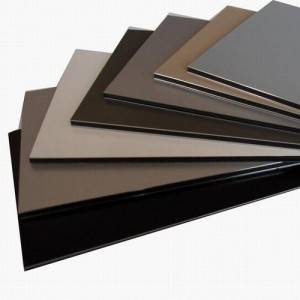

As a new type of building decoration material, aluminum composite panels have been continuously innovated since entering the Chinese market. Now the types of aluminum composite panels have also increased significantly. They are widely used in building exterior walls, curtain wall panels, and old building renovations. In buildings such as indoor wall and ceiling decoration, advertising signs, display stands. Aluminum composite panel has the following advantages

Super peeling degree

The aluminum composite panel adopts a new process to improve the peeling strength, the most important technical index of the aluminum composite panel, to an excellent state, so that the flatness and weather resistance of the aluminum composite panel are correspondingly improved.

Material is easy to process

The weight of aluminum composite panel is only about 3.5-5.5 kg per square meter, so it can reduce the hazards caused by earthquake disasters, and is easy to handle. Its superior construction performance can be cut, cut, and planed with simple woodworking tools. Various shapes such as edges, bends into arcs and right angles can cooperate with designers to make various changes, and the installation is simple and fast, reducing construction costs.

Excellent fire performance

The middle of the aluminum composite panel is a flame-retardant material PE plastic core material, and the two sides are aluminum layers that are extremely difficult to burn. Therefore, it is a safe fireproof material, which meets the fire resistance requirements of building regulations.

Impact resistance

It has strong impact resistance, high toughness, bending without damaging the finish, and strong impact resistance, and there will be no damage caused by wind and sand in areas with heavy sandstorms.

Weather resistance

Due to the use of PVDF fluorocarbon paint based on KYNAR-500, it has unique advantages in weather resistance. It will not damage the beautiful appearance no matter in the hot sun or in the cold wind and snow, and it can last for 20 years. fade.

Uniform coating and various colors

After chemical conversion treatment and the application of Henkel’s film technology, the adhesion between the paint and the aluminum panel is uniform, and the colors are diverse, allowing you to choose more space and show your individuality.

Easy maintenance

Aluminum panels have been significantly improved in terms of pollution resistance. Urban pollution in our country is relatively serious. After several years of use, maintenance and cleaning are required. Due to the good self-cleaning property, only neutral detergent and water are needed. After cleaning, the board will be permanently as new.

Easy to process

Aluminum composite panel is a good material that is easy to process and shape. It is an excellent product for the pursuit of efficiency and time. It can shorten the construction period and reduce the cost. Aluminum panels can be cut, cut, slotted, band sawed, drilled, processed countersunk, cold-formed, cold-folded, cold-rolled, riveted, screwed, or glued.

1. Good weather resistance, high strength and easy maintenance.

2. Convenient construction and short construction period.

3. Excellent processability, thermal insulation, sound insulation and excellent fire resistance.

4.Good plasticity, impact resistance, can reduce the load of the building, and good shock resistance.

5. Good smoothness, light and firm.

6. There are many colors to choose from.